How our clean-tech startup stumbled into a Pentagon partnership by following the demand

Magrathea’s founders didn’t have the Defense Department in mind when they started out—but they made the pivot.

My love for our planet began as a child growing up in rural Canada. I’m a lifelong hiker, fisherman, animal lover, and mineral collector. These interests deepened my appreciation for the value of a healthy planet.

When I moved to San Francisco, I set out to transform my passion for nature into clean-tech action. Over the next decade, I launched startups addressing major environmental challenges and worked as an advisor helping global blue-chip clients make their technologies more resilient, cost-effective, and profitable, all while being greener.

After working in natural resources, I set out on my next big venture, founding Magrathea in 2022 right here in San Francisco to develop electrolytic technology capable of creating magnesium metal from seawater—metal that could be used to manufacture electric vehicles while emitting zero CO2 emissions and reducing humanity’s need for terrestrial mining.

But world events would soon reshape our trajectory in ways I never anticipated.

A mission redefined

Our first fundraise for Magrathea, in March 2022, coincided with a turning point I never expected: the start of Putin’s full-scale invasion of the rest of Ukraine. I’m not proud to admit it—and want to be clear about that—but this horrific development, to our surprise, created momentum for Magrathea in an unexpected area: the defense industry. With the onset of the Ukraine war, the U.S. and other NATO countries immediately focused on shoring up their defenses and military spending.

Almost all military products—Black Hawk helicopters, AI-powered drones, next-generation fighter jets—require magnesium. It’s a critical component in making aluminum alloys stronger and is irreplaceable in a number of defense industry applications. Naturally, the U.S. and other NATO allies suddenly required more magnesium—and they turned to Magrathea. About a year later, we found ourselves in partnership with the U.S. Defense Department via a Defense Production Act Title III grant to further develop our technology to secure the U.S.’s defense industrial base.

Magrathea’s strategic pivot amidst the Ukraine war served as a valuable lesson. It illuminated a critical aspect of being successful with technological development: You have to make something the market wants.

To deliver successful technology, helping the environment simply isn’t enough. You need a viable technology solution in the short term with a proven end market and robust economics. Safeguarding the environment becomes a valuable byproduct, but for that benefit to be realized, the economics must work.

Small startup, big market

In the case of magnesium, our end market is expansive—magnesium metal is perhaps the most important critical material, and it’s the only structural metal you can make from seawater. You can't manufacture planes or cars without it. In addition to steel and aluminum, magnesium is also essential for titanium (aerospace applications), beryllium (electronics), and amorphous boron (defense)—as well as hafnium and zirconium (nuclear).

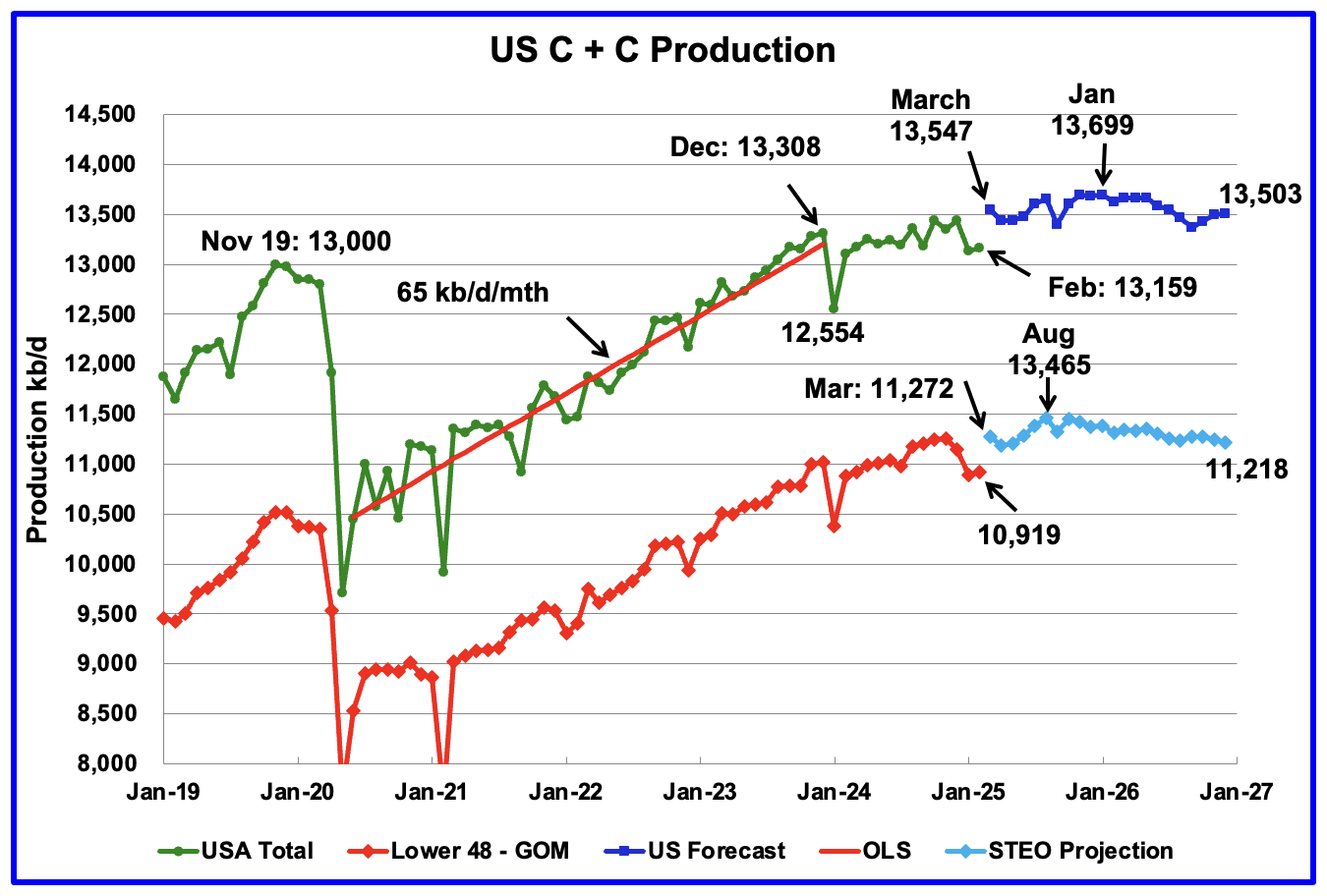

Our confidence in meeting this demand stems from historical precedent: A legacy variation of our process was used by Dow Chemical in Freeport, Texas. Using this process, Dow helped the U.S. become the world’s largest producer of magnesium metal, running the smelter for over 70 years until the late 1990s. We're building on this proven foundation with modern innovations including a major upgrade to the way magnesium chloride salt is processed before electrolysis.

Where we really differ from our predecessors is that we believe we have cracked the code when it comes to producing magnesium in a cost-effective manner by developing a less-capital-intensive, more durable salt processing and electrolysis system. We have five patent applications and mountains of trade secrets protecting the innovations we’ve imbued on the electrolytic magnesium metal production process. We’re a team of less than 20, but we’ve done more than a team of 50 could do in five years at a big company.

Good technology needs investment

As powerful and large as the market opportunity for magnesium is, having great technology is only the first step. What is most urgently needed is investment.

To ensure America becomes a leader in critical minerals and other emerging industries, billions of dollars to fund large capital projects is what will truly move the needle. This is something I have been communicating to the U.S. federal government every time I talk to them. For us, while we can produce magnesium at a small scale and sell it to customers, we need more capital to build large-scale facilities to produce the amount of metal that our customers really need.

To date, we have raised $12 million in private funding and have a $28 million partnership with the DOD, but this is only enough for us to develop our technology to pilot scale and improve processes. To take Magrathea to the next level, the government needs to understand that they must make capital available in the form of large grants and loan guarantees. The private investment industry is not going to figure this out on their own. We need the government to be first movers.

America has viable, compelling technology solutions available today to address its critical minerals shortage, but they need immense capital to scale. The Chinese understand this, and they made such capital available to build up their crucial industries decades ago. Yet our government has repeatedly missed similar opportunities, allowing promising technologies, especially clean technologies like batteries and solar photovoltaics, to be sent to their graves before being scaled up.

Climate solutions still at the heart

Climate solutions, national security, economic growth—these are not separate battles in my mind. They are one and the same. America has the chance to win them all, but that requires more than white papers, essays, and speeches. It requires focus, patience, and—most importantly—investment.

There is a path forward to bring primary magnesium metal manufacturing back to the United States to bolster national security, and to drive growth of this important and valuable industry all while bringing climate solutions to market. Now, more than ever, America has a chance to turn innovation—provided we choose to invest in it—into leadership.

As Magrathea enters the next stage of its journey—with plans to establish the first commercial electrolytic magnesium facility in the past 50 years—my climate passion is still very much with me. I don’t know for certain that the rest of my journey will be without its pivots, but one thing I do know is that I’ll never overlook the importance of building solutions that can help our planet.

The opinions expressed in Fortune.com commentary pieces are solely the views of their authors and do not necessarily reflect the opinions and beliefs of Fortune.

Read more:

- How our ping pong startup hit a $50M valuation in 5 years by tapping into automation

- How we built our bootstrapped startup different and sold it for $40M. (Hint: We ignored some myths)

- In 6 years I’ve bootstrapped my moving company to $100M in revenue. Avoiding VC funding has been key

This story was originally featured on Fortune.com